ai tools

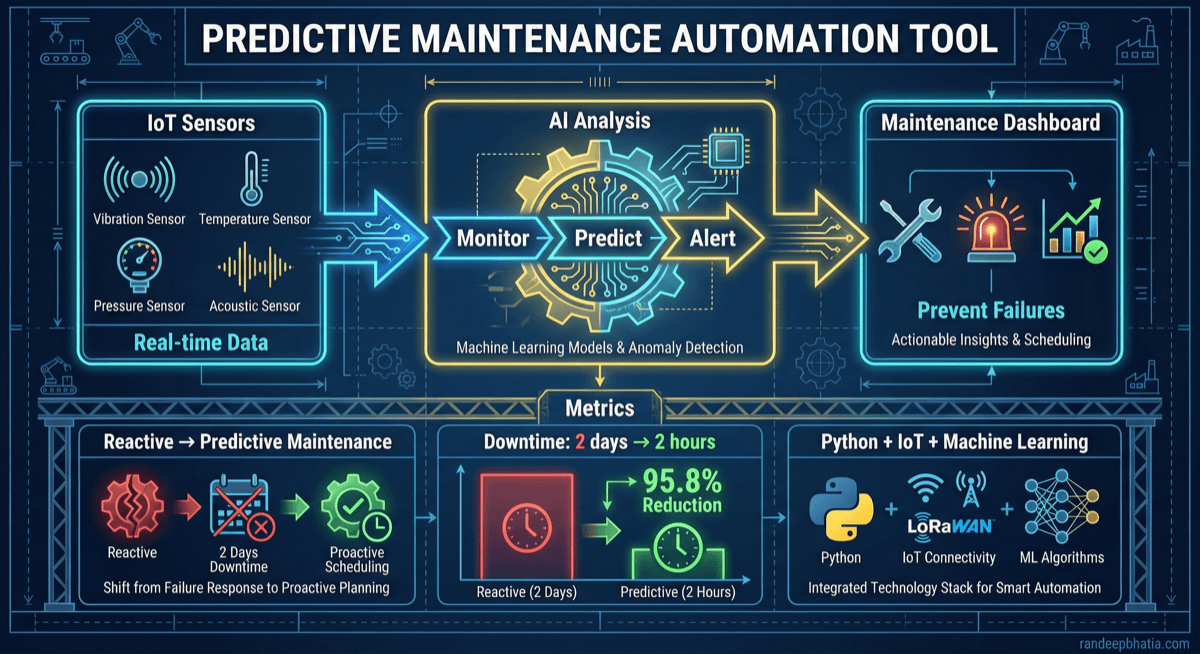

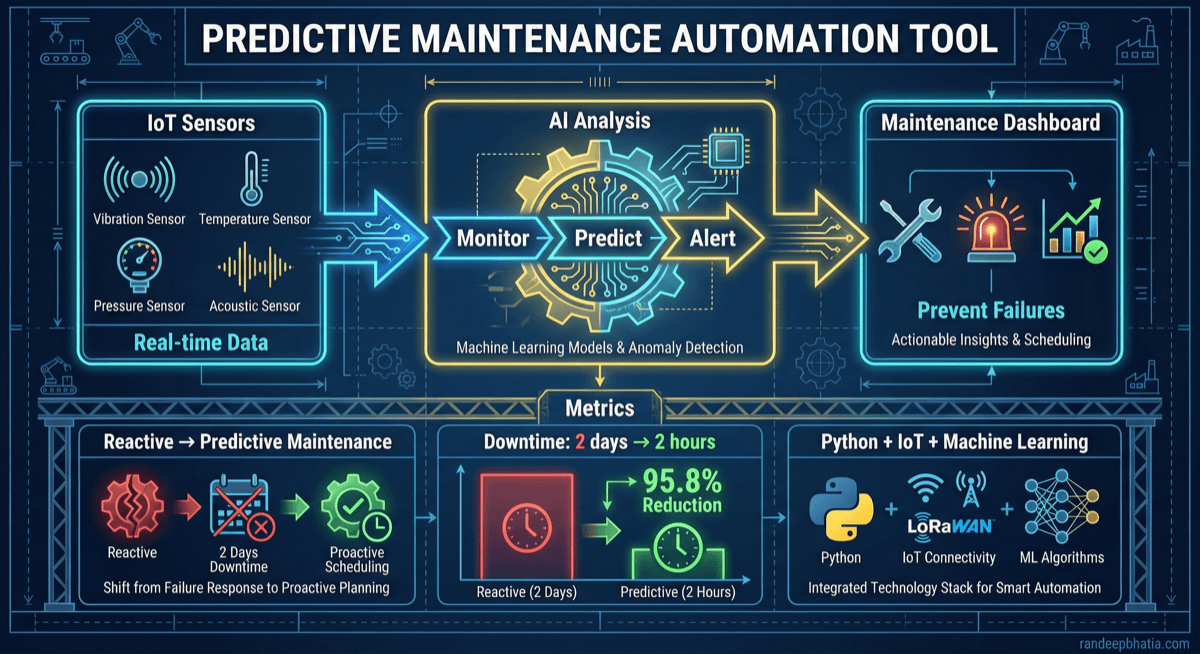

Predictive Maintenance Automation

Technical automation blueprint for predictive maintenance. Step-by-step guide for implementing AI-powered workflows.

2025-04-29

View Full Size

Technical automation blueprint for predictive maintenance. Step-by-step guide for implementing AI-powered workflows.

2025-04-29