ai architecture

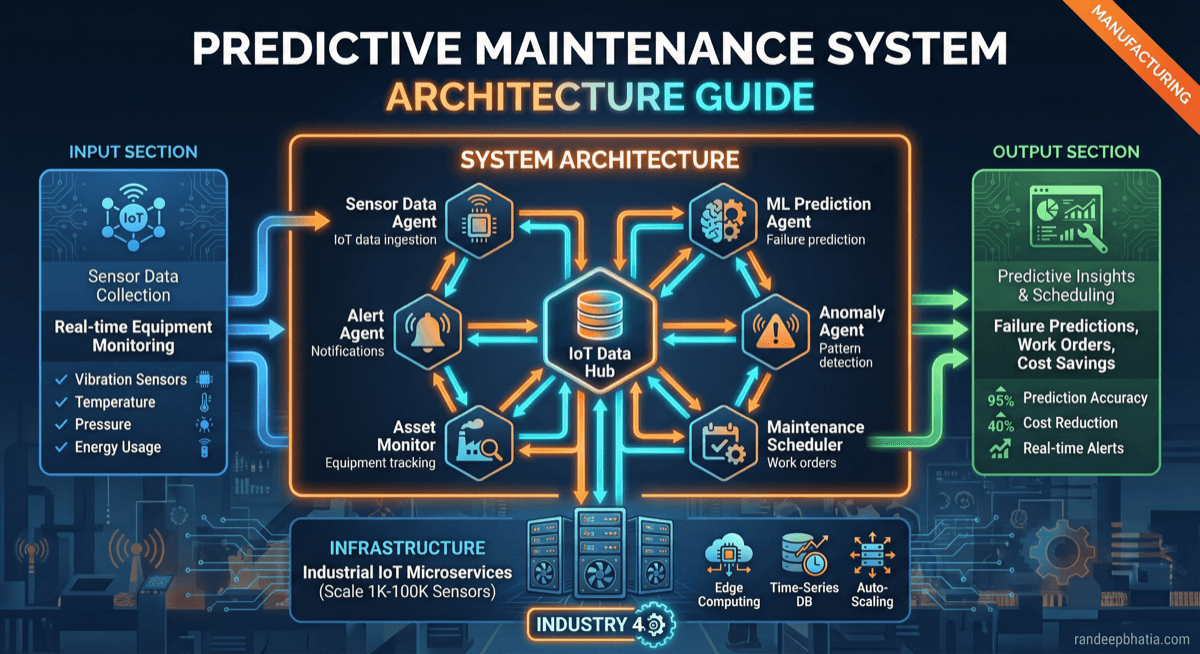

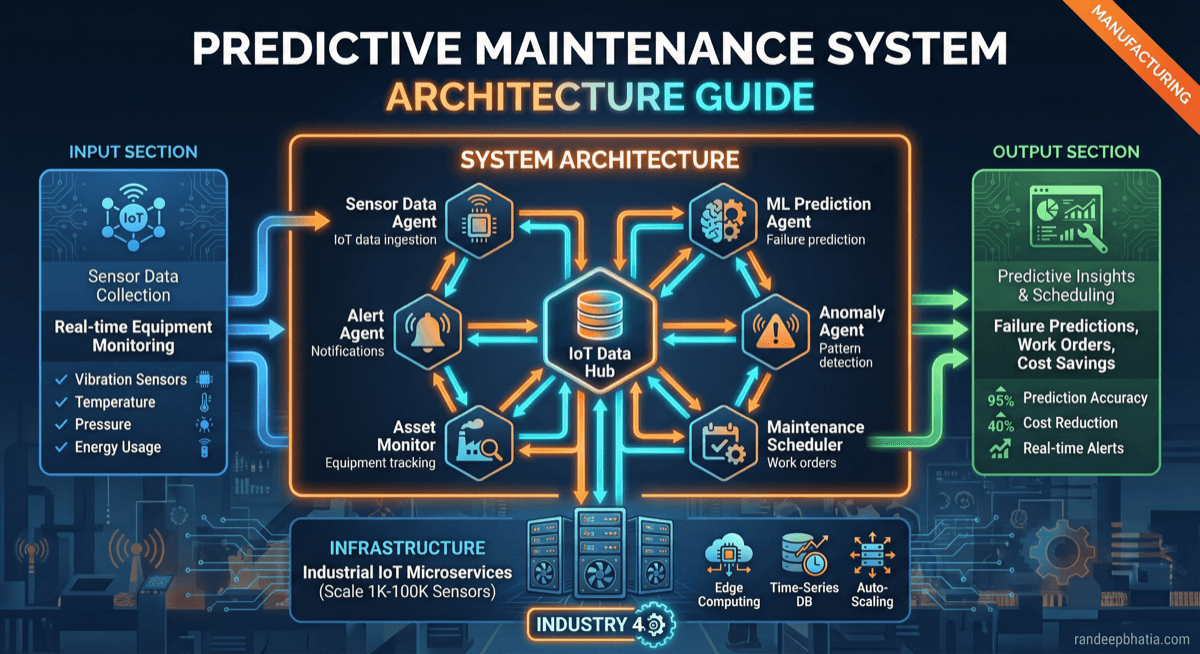

Predictive Maintenance System Architecture

Production-ready system architecture for predictive maintenance. Includes component design, data flow patterns, scaling strategies, and security considerations.

2025-05-01

View Full Size

Production-ready system architecture for predictive maintenance. Includes component design, data flow patterns, scaling strategies, and security considerations.

2025-05-01